Palm kernel oil refinery plant working principle with diagram

Tech / Chat on line / Give me a price / Date:2019-01-25

Palm kernel oil production plant

Palm kernel oil production plant

Palm kernel oil production industry becomes more and more popular, so many customers are also insterested in the palm kernel oil refinery plant. Here I will talk about Doing Company palm kernel oil refinery plant working principle in detail.

After pressing, there are many impurities in the crude palm kernel oil, which might have bad influence on the quality and flavor of the palm kernel oil. Therefore, palm kernel oil refinery plant is through four process to remove different impurities, to get refined palm kernel oil.

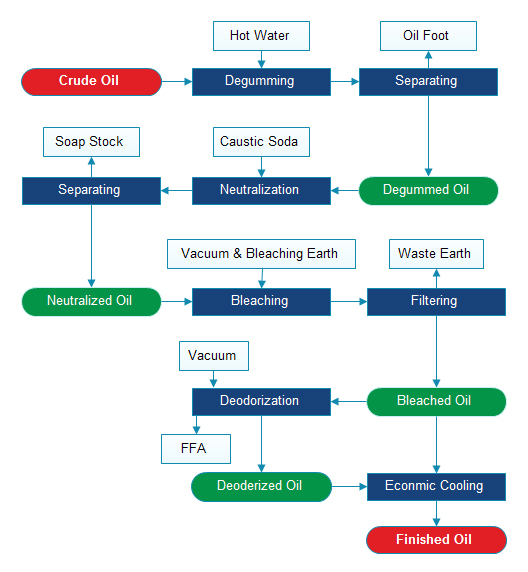

To be more specific, the palm kernel oil refinery plant includes degumming, deacidification, bleaching and deodorization four process. The following picture is DOING Company standard palm kernel oil refinery plant working principle with diagram.

Palm kernel oil refining process diagram

Palm kernel oil refining process diagram

In palm kernel oil refining process, the degumming process and deacidification process is almost simultaneously. The gums and fatty acids in crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid and alkali.

In bleaching process, the palm kernel oil is mixed with bleaching earth (White clay) in a vacuum room, and the bleaching earth absorb impurities and colour pigments in palm kernel oil, at last, leaf filter to remove bleaching earth, to get bleached palm kernel oil.

In deodorization process, the odour and taste of the palm kernel oil are removed when the oil is steamed at high temperatures of between 240°C to 260°C, and then cooled to room temperature, filtered in safe filter, at last pumped into palm kernel oil storage tanks.