Palm oil fractionation plant

Batch Type Edible Oil Refinery / Chat on line / Give me a price / Date:Nov 07, 2017

Palm oil fractionation plant Introduction:

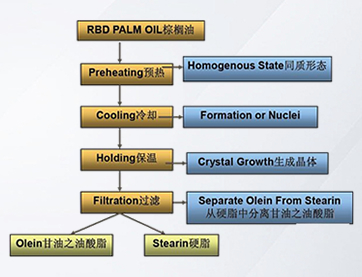

Palm oil fractionation plant goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (sterin). Fractionation of palm oil can be divided into three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm midfraction).

After palm oil fractionation plant, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance.

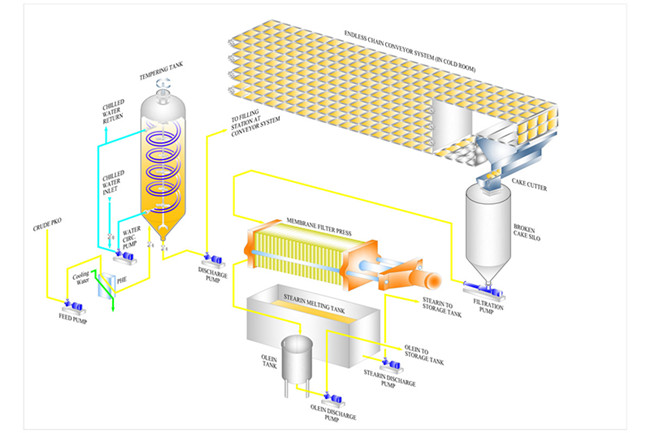

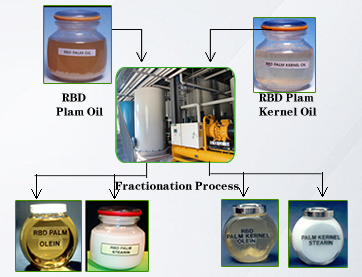

Palm oil fractionation plant process chart:

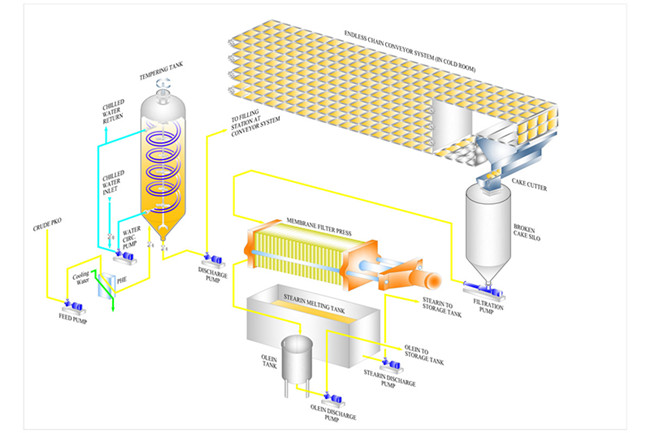

Working principle of palm oil fractionation plant:

Palm oil fractionation plant uses mechanical separation of liquid oil from solid fractions of certain oil and fats. It can greatly maximize the value of products.

Dry Palm Oil Fractionation Plant Principle:

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester.

Dry palm oil fractionation plant includes three steps below:

Heat treatment

Form crystal nuclei and allow crystal growth and maturity by cooling method.

Filtration separates soft fat from solid.

One time fractionation is enough, but twice palm oil fractionation is in need for some relatively high demand industry of stearin, such as confectionery industry.

Featured Advantages of dry palm oil fractionation plant:

◆Simple oil fractionation process

◆Easy and convenient operation

◆Low consumption of steam

◆No environmental pollution

◆Satisfied palm oil fractionation results

Factors affecting dry palm oil fractionation plant:

◆ Design of crystallizers

◆ Filter cloth air permeability (400, 600 L/dm2/min)

◆ Filling and Squeezing pressure

◆ Poor Control of Cooling Water Temperature

Palm oil fractionation plant goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (sterin). Fractionation of palm oil can be divided into three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm midfraction).

Palm oil fractionation plant workshop

Palm oil automatic control dewaxing and degreasing process work under slowly stirring and cooling the oil to certain temperature in fixed time (technical security), and make waxy formed bigger crystallization, then separation exhalation, after filtering, it separates the fluid oil and solid fat.After palm oil fractionation plant, palm oil will be clean after 5.5 hours in 0 degree Celsius, but it also can keep transparency and flowability in the refrigerator and improve the oil quality and appearance.

Palm oil fractionation plant process chart:

|

|

Palm oil fractionation plant process flow chart

Working principle of palm oil fractionation plant:

Palm oil fractionation plant uses mechanical separation of liquid oil from solid fractions of certain oil and fats. It can greatly maximize the value of products.

Dry Palm Oil Fractionation Plant Principle:

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester.

Dry palm oil fractionation plant includes three steps below:

Heat treatment

Form crystal nuclei and allow crystal growth and maturity by cooling method.

Filtration separates soft fat from solid.

One time fractionation is enough, but twice palm oil fractionation is in need for some relatively high demand industry of stearin, such as confectionery industry.

Featured Advantages of dry palm oil fractionation plant:

◆Simple oil fractionation process

◆Easy and convenient operation

◆Low consumption of steam

◆No environmental pollution

◆Satisfied palm oil fractionation results

Factors affecting dry palm oil fractionation plant:

◆ Design of crystallizers

◆ Filter cloth air permeability (400, 600 L/dm2/min)

◆ Filling and Squeezing pressure

◆ Poor Control of Cooling Water Temperature

Call us

Call us Chat online

Chat online