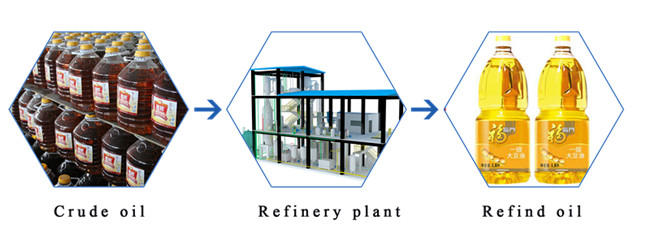

Degumming process of edible oil refinery plant

Batch Type Edible Oil Refinery / Chat on line / Give me a price / Date:Nov 07, 2017

Edible oil refinery plant

The oil is delivered to the degumming process by the feed pump. It is heated to 65 - 70 C in the Crude Oil Heater by steam in the Feed Heater and then mixed with acid solution in the Mixer. The mixture is delivered to reaction vessel with agitator for completion of reaction. The mixture from reaction vessel is cool down to 25-30 Deg C and mixed with desired quantity of water. This mixture is delivered to hydration vessel with agitator for coagulation of phosphatides..

The coagulate mass is transferred to centrifugal separator through heater to heat the oil 70-80 Deg C. for separation of gums from oil. Separated gums are collected in gum tank and delivered to storage or to desolventizer toaster. Degummed oil from separator is transferred via heat exchanger to vacuum drier for removal of moisture from oil. Dried oil from drier is delivered to dried oil storage tank.

Call us

Call us Chat online

Chat online