1-20TPD edible oil refining equipment plant

Batch Type Edible Oil Refinery / Chat on line / Give me a price / Date:Nov 07, 2017

Refining is an essential process for a complete edible oil production line because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude oil. As a prominent oil processing machines manufacturer who is devoted to processing pure edible oil for worldwide customers, we can product and offer professional technical edible oil refining equipment plant for your edible oil refining. We can provide turnkey oil refining solution with capacities from 1-20T/D.

Edible oil production machine

1-20T/D Edible Oil Refining Equipment Plant Features:

1. Wide application: various kinds of oil can be refined by our edible oil refining equipment plant such as peanut oil, sunflower seeds oil, soybean oil, coconut oil, palm kernel oil, rapeseed oil, etc.

2. The capacity of edible oil refining equipment plant can be customized. The complete edible oil refining plant can work independently or together with whole oil production line.

1.Degumming : In this step of edible oil refining equipment plant gums in crude oil are removed by hydration with the help of phosphoric acid.

2. Neutralization: In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Bleaching: During bleaching process of edible oil refining equipment plant, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization: Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

5. Dewaxing (necessary for cold areas)

Some kinds of oil like sunflower, maize germ or corn oil have waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance. so this process is necessary in extremely cold areas.

Edible oil refining equipment plant

Main Parts of Edible Oil Refining Equipment Plant :

1. Decoloring tank: bleach pigments from oil.

2. Deodorizing tank: remove the un-favored smell from decolorized oil.

3. Oil furnace: provide enough heat for the refining sections which need high temperature of 280℃.

4. Vacuum pump: provide high pressure for bleaching, deodorization which can reach 755mmHg or more.

5. Air compressor: dry the bleached clay after bleaching.

6. Filter press: filter the clay into the bleached oil.

7. Steam generator: generate steam distillation.

Main technical parameters of edible oil refining equipment plant:

Edible oil production machine

1. Wide application: various kinds of oil can be refined by our edible oil refining equipment plant such as peanut oil, sunflower seeds oil, soybean oil, coconut oil, palm kernel oil, rapeseed oil, etc.

2. The capacity of edible oil refining equipment plant can be customized. The complete edible oil refining plant can work independently or together with whole oil production line.

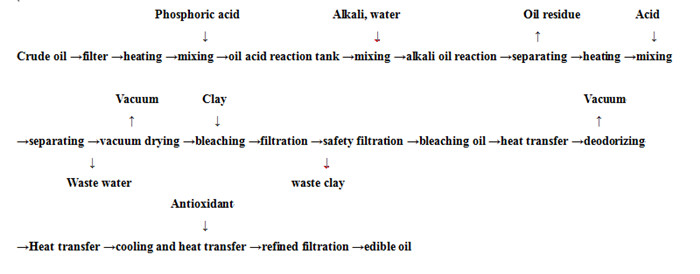

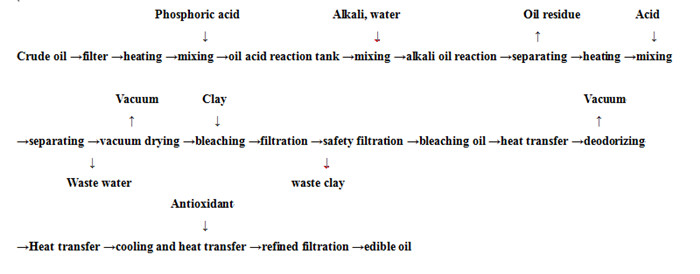

Edible oil refining process

Main Steps of 1-20TPD Edible Oil Refining Equipment Plant:1.Degumming : In this step of edible oil refining equipment plant gums in crude oil are removed by hydration with the help of phosphoric acid.

2. Neutralization: In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Bleaching: During bleaching process of edible oil refining equipment plant, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization: Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

5. Dewaxing (necessary for cold areas)

Some kinds of oil like sunflower, maize germ or corn oil have waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance. so this process is necessary in extremely cold areas.

Edible oil refining equipment plant

1. Decoloring tank: bleach pigments from oil.

2. Deodorizing tank: remove the un-favored smell from decolorized oil.

3. Oil furnace: provide enough heat for the refining sections which need high temperature of 280℃.

4. Vacuum pump: provide high pressure for bleaching, deodorization which can reach 755mmHg or more.

5. Air compressor: dry the bleached clay after bleaching.

6. Filter press: filter the clay into the bleached oil.

7. Steam generator: generate steam distillation.

Main technical parameters of edible oil refining equipment plant:

| Steam consumption | 700KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Alkali | acid valuex1-3kg/T oil |

| Circulating water cooling water yield | 150M3/ |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses |

acid valuex1.2 (chemical refining) acid valuex 0.6 (physics refining) |

| Bleaching losses | the quantity of bleaching earth×0.25% |

| Deodorization loss consumption | ≤0.5%≤0.5% |

| Refining rate | 1-refining consumption |

Call us

Call us Chat online

Chat online