How to refine crude cottonseed oil into product oil?

Tech / Chat on line / Give me a price / Date:2023-01-11

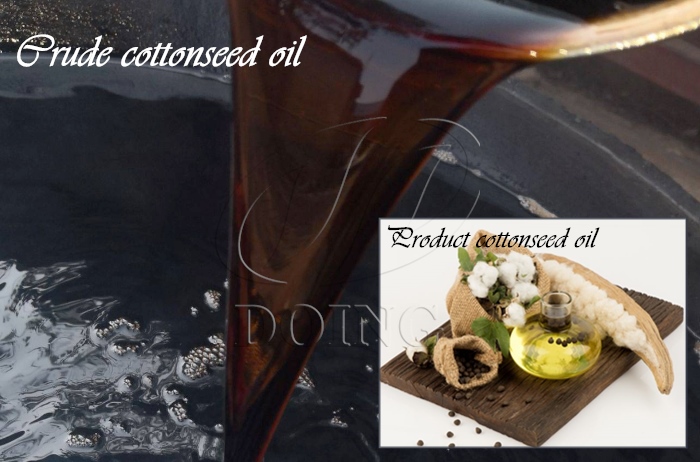

Crude cottonseed oil is got from pressing plant or solvent extraction plant, including many impurities. If you want get high quality cottonseed oil, the refining process is necessary. How to refine crude cottonseed oil into product oil, in the cottonseed oil refinery plant? If you are interested in it, please continue reading.

Crude cottonseed oil and product cottonseed oil

Crude cottonseed oil and product cottonseed oil

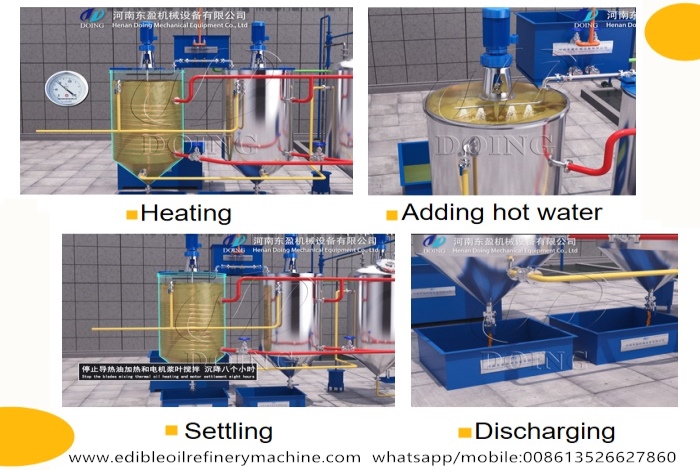

First of all, it is cottonseed oil degumming process, which is to remove the colloidal impurities in crude cottonseed oil. What is the colloidal impurities? Colloidal impurities include the phospholipid, protein, phlegmatic temperament and glycosyl diglycerol. These colloidal impurities will influence the stability of cottonseed oil and the effect of cottonseed oil refining and further processing.

The degumming method has two kinds: water degumming process and dry degumming process. Cottonseed oil degumming usually uses water degumming process. The specific operation is to add a certain amount phosphoric acid solution, which can make the colloidal impurity absorb water for cohesion. Then the colloidal impurities will sink to be separated with oil.

Water gegumming process of cottonseed oil

Water gegumming process of cottonseed oil

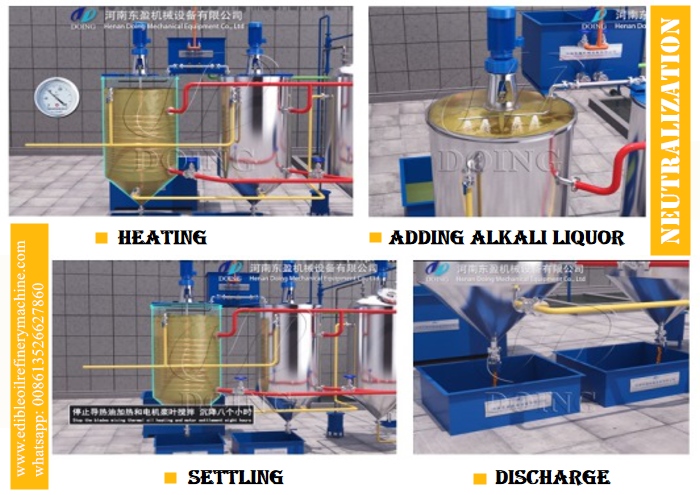

Secondly, it is the process of removing the free fatty acid from crude cottonseed oil, called cottonseed oil deacidification. Free fatty acid is also called FFA, which is the main factor to make the oil rancidity, so it should be removed.

Cottonseed oil deacidification process has two kinds: chemical and physical. The chemical deacidification process is to add alkali liquor to react with FFA to generate nigre and the physical deacidification process is using high temperature steam to distill the FFA out.

The process of cottonseed oil chemical deacidification

The process of cottonseed oil chemical deacidification

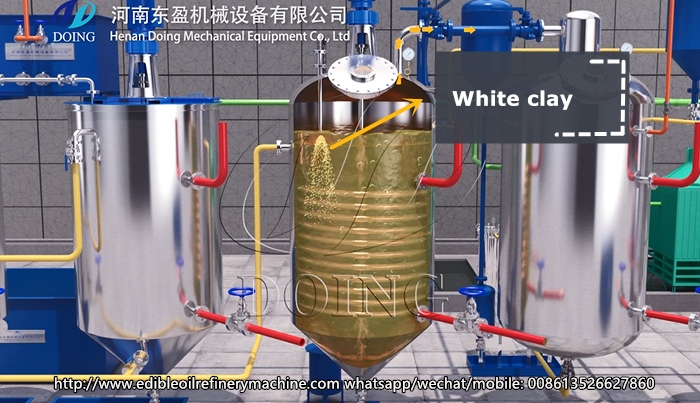

After deacidification, the crude cottonseed oil need to be decoloried by bleaching method. It is usually to use white clay to absorb the pigments, at same time absorbing residual gums and soapstocks. And then through filtering by plate filter, the waste clay will be filtered out. Cottonseed oil decolorization process is mainly to make the oil color more lighter, and qualified the national standard.

Add white clay to remove the pigment from crude cottonseed oil

Add white clay to remove the pigment from crude cottonseed oil

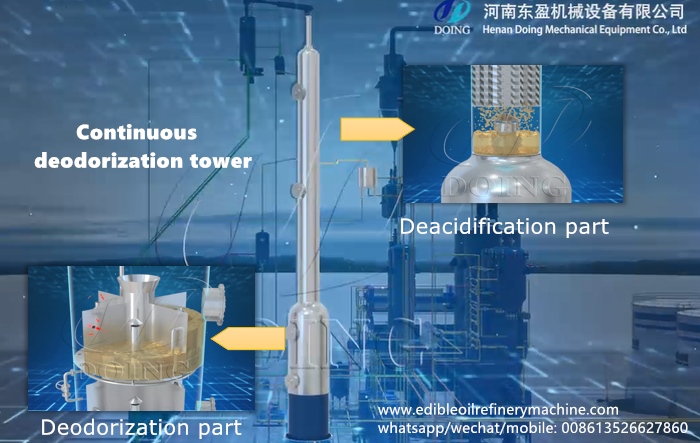

Fourthly, it is time to solve the smell problem. It is called cottonseed oil deodorization process. It often uses distillation principle, injecting high temperature steam to distill the odors out. The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil.

The deodorization tower used in continuous cottonseed oil refinery plant

The deodorization tower used in continuous cottonseed oil refinery plant

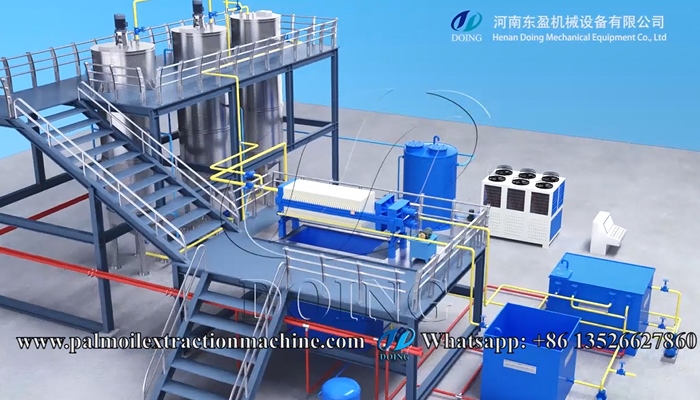

At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature. Similar with palm oil fractionation process, through cooling, crystallization and filtration, you can get two parts: cottonseed oil olein and cottonseed oil stearine.

The cottonseed oil winterization equipment

The cottonseed oil winterization equipment

Cottonseed oil has very large production in some countries, such as China, India, Pakistan, the United States, Brazil, and Turkey. If you have plenty of raw materials, you can consider starting cottonseed oil production business. Doing Company can provide not only cottonseed oil refining machine but also cottonseed oil pressing equipment and solvent extraction equipment. Welcome you to contact us!