Edible oil refining process flow chart introduction

Tech / Chat on line / Give me a price / Date:2019-04-12

Edible oil refining process flow chart is usually designed by engineers according to customer's plant area and process requirements. Generally, edible oil refining process flow chart has three types based on the input capacity, batch type edible oil refining process flow chart, semi- continuous edible oil refining process flow chart and full-continuous edible oil refining process flow chart.

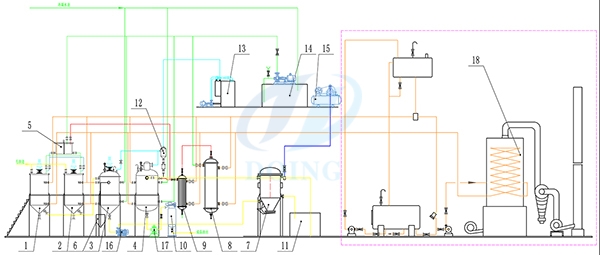

1. Batch type edible oil refining process flow chart introduction

Batch type edible oil refining process flow chart is suitable for 1-20tpd edible oil refinery plant. It uses chemical refining method, because of adding alkali to remove free fatty acid in deacidification process.

Batch type edible oil refining process flow chart(Click here for larger view)

Batch type edible oil refining process flow chart(Click here for larger view)

Crude oil --Degumming --Deacidification --Decolorization --Deodorization --Refined oil

Batch type edible oil refining process is the best choice for small scale edible oil refinery plant, low cost, small footprint.

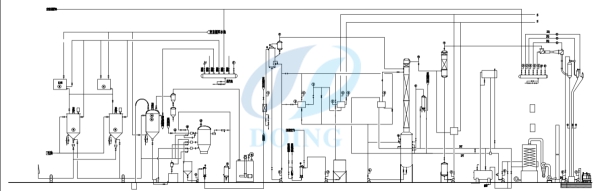

2. Semi-continuous edible oil refining process flow chart

Semi-continuous edible oil refining process flow chart is suitable for 10-50tpd edible oil refinery plant. It has a deodorizing tower, so it also can use physical method to remove free fatty acid.

Semi-continuous edible oil refining process flow chart(Click here for larger view)

Semi-continuous edible oil refining process flow chart(Click here for larger view)

If your crude oil has high acid value, deacidification process will be twice in the whole edible oil refining process. One is adding alkali, belongs to chemical method, and the other is steaming in the deodorizing tower, belong to physical method. Such edible oil refining process has the best effect of deacidification.

A combination of physical and chemical methods:

Crude oil --Degumming --Deacidification --Decolorization --Deodorization and Deacidification --Refined oil

Compared to batch type edible oil refining process, the semi-continuous edible oil refining process has better refining effect, but with high cost.

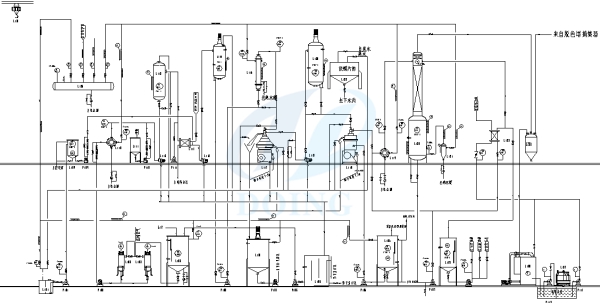

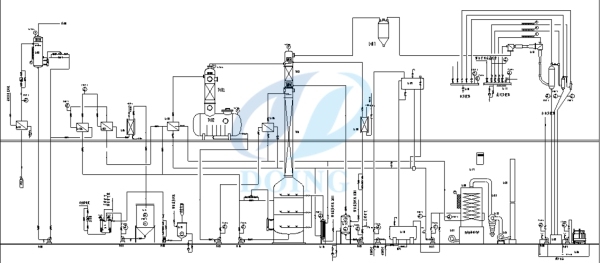

3. Full-continuous edible oil refining process flow chart

Full-continuous edible oil refining process flow chart is suitable for 30-2000tpd edible oil refinery plant. It is totally different from batch type and semi-continuous edible oil refining process flow chart, which is more complicated and need more equipment.

In full-continuous edible oil refining process, the degumming and deacidification process are simultaneous. And then decolorization process and deodorization process is all finished in tower. The whole edible oil refining process is continuous and self-controlled. Generally, it uses the combination of physical and chemical methods, same as semi-continuous edible oil refining process flow.

The degumming and deacidification process flow chart:

Degumming and Deacidification process flow chart(Click here for larger view)

Degumming and Deacidification process flow chart(Click here for larger view)

The decolorization process flow chart:

Decolorization process flow chart(Click here for larger view)

Decolorization process flow chart(Click here for larger view)

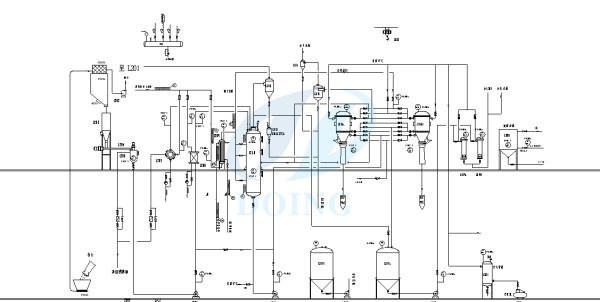

The deodorization process flow chart:

Deodorization process flow chart(Click here for larger view)

Deodorization process flow chart(Click here for larger view)

Crude oil --Degumming --Deacidification --Decolorization --Deodorization and Deacidification --Refined oil

However, if your crude oil is palm oil, it will use palm oil physical refining process.

Crude palm oil --Dry degumming method ----Decolorization --Deodorization and Deacidification --Refined palm oil --Fractionation --palm stearin and palm olein

If you are insterested in palm oil physical refining process, please watch our video: Continuous palm oil physical refinery process (3D video)

This is all the introduction about edible oil refining process flow chart. Any questions, welcome to contact Henan Doing Company, which is a professional edible oil refinery machine manufacturer, and our engineers will answer your questions.