Crude palm oil refining machine and palm oil refining process flow chart

Tech / Chat on line / Give me a price / Date:2023-09-13

Crude palm oil, crude palm oil can be obtained through press or palm oil press

Crude palm oil, crude palm oil can be obtained through press or palm oil press

Why does crude palm oil need to be refined? What are the crude palm oil refining machines?

Crude palm oil is difficult to introduce into the market because it contains free acids (FFA), moisture, trace metals and other impurities that limit its shelf life. In order to obtain high-quality palm oil, crude palm oil needs to be refined through palm oil refining machine. The purpose of palm oil refining is to remove phospholipids, FFA, pigments, gums, waxes, odors and other impurities in crude palm oil.

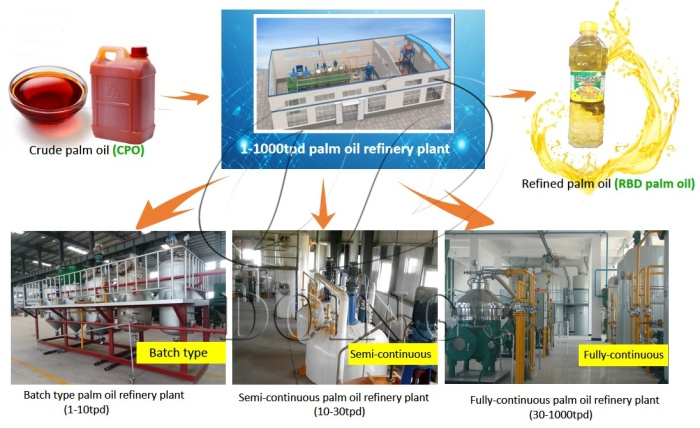

We can provide palm oil refining machine from 1 ton to 1000 tons. Generally speaking, the production capacity of batch type palm oil refining machine is 1-20TPD; the recommended production capacity of semi-automatic palm oil refining machine is 20-50TPD; the continuous palm oil refining machine is used for production capacity above 50TPD.

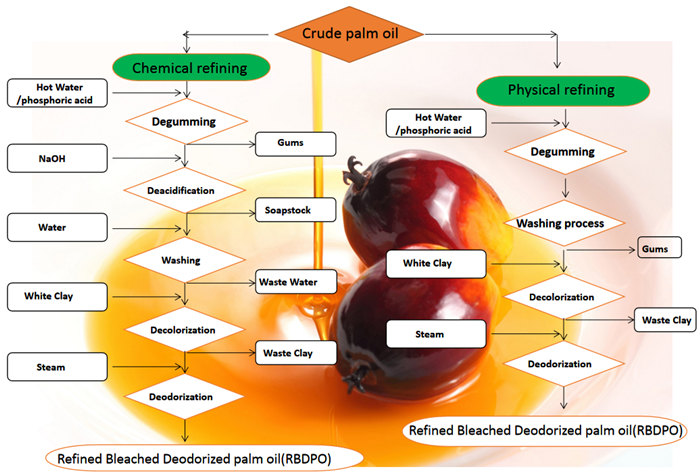

Chemical refining and physical refining of crude palm oil

Chemical refining and physical refining of crude palm oil

In the palm oil refining process, two refining methods can be used, namely chemically refined palm oil and physically refined palm oil. The main difference between physical and chemical refining of palm oil is how FFA are removed. Chemical refining removes FFA in the deacidification section, and physical refining removes FFA in the deodorization section. The main processes of palm oil refining process are: degumming, deacidification, decolorization and deodorization.

Therefore, we should consider the characteristics of different raw edible oils and then choose the best refining method. For crude palm oil, we usually use physical refining to remove FFA. Let me introduce the refining process of palm oil:

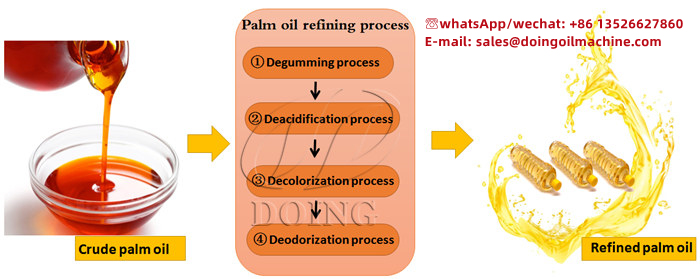

Palm oil refining process flow chart:

Batch type palm oil refining process flow chart

Batch type palm oil refining process flow chart

Introduction to palm oil refining process:

Degumming section: This is the first step in palm oil refining, also known as the pretreatment process. During the degumming process, the gum precipitates and separates.

Neutralization Fraction: Every cooking oil contains a certain amount of free fatty acids, FFA, which increase the rancidity of the oil and are harmful to human consumption. During neutralization, FFA is removed by reacting with caustic soda-NaOH at a certain temperature in the neutralizer and stirring.

Bleaching Part: The pigments in the oil are removed during the bleaching process.

Deodorizing Section: This process is used to remove odors from the oil. Every oil contains a certain characteristic natural color. It is performed under high temperature and vacuum system. After the deodorization process is completed, we get deodorized and tasteless cooking oil. After the crude palm oil refining process, the palm oil refined products are RBD palm oil and soap. Refined palm oil can be sold directly or further processed. If refined palm oil requires further processing, palm oil fractionation machine is required. After palm oil is fractionated, palm olein and palm stearin can be obtained.

Palm oil refining products (After palm oil extraction process, we can get crude palm oil, after palm oil refining process, we can get RBD palm oil, after palm oil fractionation process, we can get palm olein and palm oil stearin)

Palm oil refining machine

Palm oil refining machine

Our company is a company specializing in palm oil refining machine, and our engineers can help you design the entire palm oil refinery according to your capacity and requirements. We can provide palm oil refining equipment, palm oil refining process flow diagram, palm oil refinery layout design, palm oil refinery project installation training guide, etc. If you are interested in palm oil refining business, please contact us.