How effective is a 2 ton per day edible oil refining machine? How much does it cost?

Tech / Chat on line / Give me a price / Date:2023-09-27

Some small and medium-sized edible oil processing factory owners always have concerns when purchasing edible oil refining machine, worrying that the performance of small edible oil refining machine is not up to standard. As a manufacturer that has been engaged in the oil refining industry for more than ten years, Henan Glory Company can tell you responsibly that the effect of small edible oil refining machine is actually the same as that of large edible oil refining machine. They all undergo degumming, deacidification, decolorization, and deodorization. Wait for a complete process to remove impurities in the crude oil, and the refined oil finally obtained has a clear color, is not easy to settle, has a long storage time, and can meet the national standards for edible oil. The difference may lie in the initial capital investment, processing volume and later operating efficiency.

small edible oil refining machine

small edible oil refining machine

Below, Henan Glory Company will take a 2 ton per day edible oil refining machine as an example to explain in detail the process, advantages, price budget, and other details of small edible oil refining machine to help you understand the equipment's refining effect and price information.

1. 2 tons per day edible oil refining machine refining process

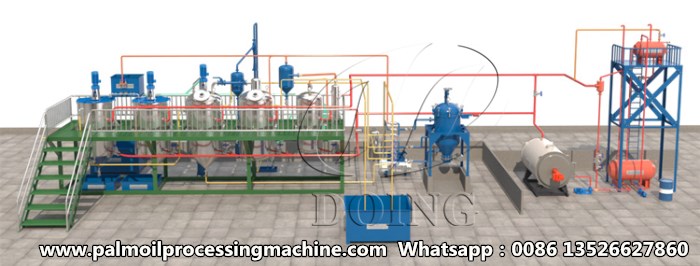

The refining process of 2 tons per day small edible oil refining machine generally adopts chemical refining technology, using the principles of hydration degumming, alkali deacidification, clay decolorization and distillation deodorization to remove impurities from the crude oil. The specific process is shown in the following 3D video:

Degumming: Crude oil contains peptized impurities, which will affect the stability of the oil. During degumming, we add a certain amount of hot water and electrolyte solution to the crude oil while stirring. The peptized impurities in the crude oil begin to absorb water and They swell and agglomerate to form a rubber ball-like substance. As the water is drained, they are also separated from the oil.

Degumming and deacidification

Degumming and deacidification

Deacidification: Add a certain concentration and a certain amount of NaOH to perform an acid-base neutralization reaction to achieve the purpose of removing free fatty acids in the oil.

Decolorization: In the decolorization section, white clay is mainly used for adsorption and decolorization. The dosage of white clay accounts for about 2%-3% of the oil. The temperature is about 100 degrees. After the reaction for half an hour, filter equipment is used to separate the grease from the decolorizing agent, thereby To achieve the purpose of decolorization.

Decolorization section

Decolorization section

Deodorization: Vegetable oils have their own unique odor. After deacidification and decolorization, the oil will also have the smell of trace oxides and residual solvents of white clay. The process of removing these bad odors is called deodorization. Under high temperature 220-260°C and vacuum conditions, a certain amount of superheated steam is introduced to strip the oil, and deodorization is achieved according to the different volatilization points of the grease and volatile small molecular substances.

Deodorization tank

Deodorization tank

Through the above four steps, suspended impurities, peptidic impurities, fat-soluble impurities and other impurities in the oil can be effectively removed, the flavor and color of the oil can be improved, and the refined oil can meet national standards.

Edible oil refining process

2. 2 tons per day edible oil refining machine advantages

Small footprint: The 2 tons per day small edible oil refining machine has a compact structure and a relatively small footprint. It can be flexibly designed according to user needs and can adapt to different sites and environments. The site requirements are not very high.

Can be customized according to needs: The 2 ton per day edible oil refining machine produced by Henan Glory Company can be made of different materials according to customer needs, such as: 201 stainless steel, 304 stainless steel or a combination of carbon steel + stainless steel; the heating method can be electric heating. method or thermal oil heating method.

2 ton per day edible oil refining machine with electric heating

2 ton per day edible oil refining machine with electric heating

Selection of high-quality raw materials for processing: Henan Glory Company will select high-quality raw materials for processing according to customer needs. The thickness of carbon steel material is guaranteed, and the stainless steel material is 201 or 304. Finished edible oil refining equipment is resistant to high temperatures, corrosion and has a longer service life.

In addition, 2 ton per day edible oil refining machine also has the advantages of simple operation, low energy consumption, and the ability to easily change the type of crude oil. Moreover, the initial investment cost is low and the equipment is cheap. For small and medium-sized edible oil processing plants, small edible oil refining machine is a practical choice.

3. 2 tons per day small edible oil refining machine price

The price of 2 tons per day edible oil refining machine is about US$13,000-50,000. The specific price needs to be selected according to the customer's needs, such as heating method, equipment material, oil quality requirements, etc.

The electric heating method has simple equipment. It heats directly through electricity and does not require additional equipment. The thermal oil heating method requires a thermal oil furnace system. The initial investment is larger than that of the electric heating method, but the thermal oil can be recycled and the later operating costs are lower.

If you want a specific price for 2 tons per day edible oil refining machine, please leave a message below or contact us directly by phone. Henan Glory Company will arrange a business manager to communicate with you about your specific needs and give you a detailed plan quotation.