Soybean oil refinery plant

Solution / Chat on line / Give me a price / Date:2021-01-27

How to set up a soybean oil refinery plant? How much it will cost to set up a soybean oil refinery plant? These two questions are often asked by our customers. In fact, it is very hard to explain to you in several sentences exactly.

Generally, you need do some preparation, make the project plan, choose soybean oil refinery machine manufacturer, choose soybean oil refining process, etc. Or you can contact with us, and our project manager can guide you step by step. For example, how to decide the workshop location and size, how to choose the suitable refining process based on your budget, etc.

As a professional edible oil refinery plant manufacturer in China, Henan Doing Company can provide you three types soybean oil refinery plant with factory price, according to different input capacities. They are: 1-20tpd batch type soybean oil refinery plant; 20-50tpd semi-continuous type soybean oil refinery plant; 30-1000tpd full-continuous type soybean oil refinery plant.

Three types soybean oil refinery plants

Three types soybean oil refinery plants

So, you need confirm the input capacity you want. If you have a soybean oil processing plant, you can decide according to the daily output of it. If you want to buy crude soybean oil from others, you need make sure that you have stable daily supply.

As for which type equipment you need choosing, it depends on your requirement of product oil and your budget. For example, if you want to set up a 20tpd soybean oil refinery plant, you can choose batch type or semi-continuous type soybean oil refinery plant. Of course, semi-continuous type has better refining effect, but it costs more.

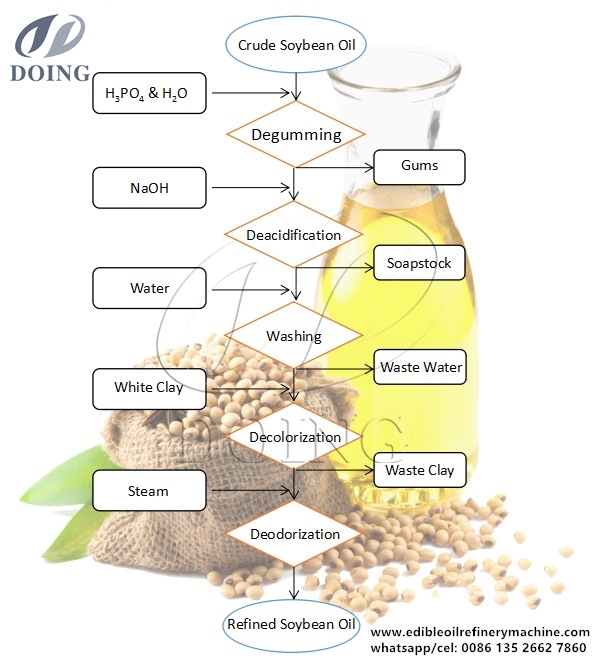

Next, you should learn about the soybean oil refining process. The following picture is the soybean oil refining process flow chart that is made based on our engineers' design.

Soybean oil refining process flow chart

Soybean oil refining process flow chart

1. The degumming process in soybean oil refining process:

Soybean oil has high gums content. Usually use hydration degumming process to remove gums from crude soybean oil with the help of phosphoric acid.

2. The Deacidification (neutralization) process in soybean oil refining process:

In batch type soybean oil refinery plant, free fatty acids are neutralized by using alkali, and then are converted into soap stock. At the same time, additional impurities are also removed by soap stock adsorption.

In semi-continuous and full-continuous type soybean oil refinery plant, you can choose physical refining method to remove the free fatty acids. It is using steam to bring the free fatty acids out, and then collects the free fatty acid into a tank.

3. The Decolorization process in soybean oil refining process:

Decolorization process is using white clay to adsorb unwanted pigments and then the color of soybean oil will become much lighter.

4. The Deodorization process in soybean oil refining process:

Deodorization process is to remove unacceptable odors by steam distillation. In the process, the odoriferous compound are stripped off by injecting steam into heated oil under high vacuum pressure.

These are the brief introduction about soybean oil refining process. The project manager and our engineer will also explain it for you. Besides, we have the soybean oil refining process 3D animation to help you understand.

Welcome to Zhengzhou, Henan province to visit our office and factory! Henan Doing Company will provide best service for you to help you set up your soybean oil refinery plant.