Peanut oil press machine

SOLUTION-old / Chat on line / Give me a price / Date:May 18, 2016

Pretreatment and prepressing section is a very important section before extraction. It will directly affect extraction effect. The set of peanut oil pretreatment and prepressing machine includes cleaning, dehulling, crushing,flaking,cooking and prepressing sections and so on.

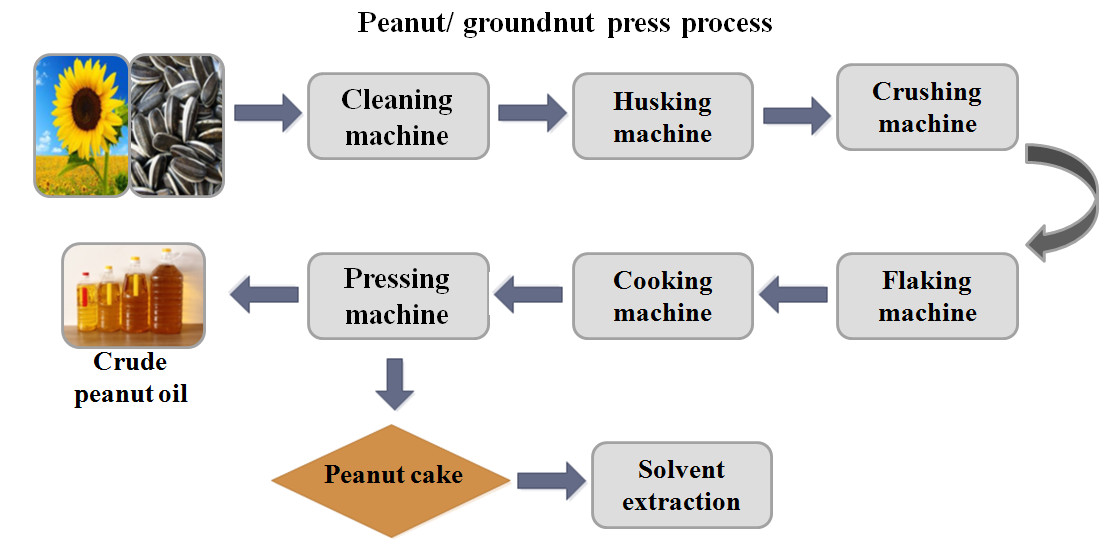

Peanut / groundnut oil pretreat process

1> Cleaning :

Machines needed in cleaning include magnetic separator, cleaning seive, winnowing machine, etc, removing mechanical impurities such as soild, iron impurities, sick seeds, etc. Cleaning prevents following equipments from demage and increases oil yeild as an essential part pf peanut oil extraction plant.

2> Husking :

The main ingredients of peanut shells is fiber, wich would hinder peanut oil extraction . Husking separates hulls from peanuts to improve the oil yielding rate, crude oil quality and meal quality.

3> Crushing:

Peanut kernel is big in size; crushing machine/crusher breaks peanut kernel to smaller pieces to impove pressing effect.

4> Flaking:

Flaking damages oil cells, increases oil surface, and shortens the oil outflowing distance, which benefits oil extraction and impoves cooking efficiency.

5> Cooking:

This process can improve prepressing oil yield rate and meal quality, and also adjust the moisture, temperature and plasticity of the flake.

6> Pressing:

This section to squeeze out part of the oil in the raw material, and improve extracting effect.

As manufacturer of peanut oil press machine, we can offer whole line or parts of peanut oil press machine with general capacity from 5TPD to 2000TPD. For special capacity, our engineers can also help you design and install workshop according to your capacity and requirements.If you're interested in peanut oil press machine, please feel free to contact us.

Call us

Call us Chat online

Chat online