Palm oil refinery plant

Solution / Chat on line / Give me a price / Date:2021-01-27

After extracting palm oil, the crude palm oil is sent to palm oil refinery plant for refining. Through several refining steps to remove free fatty acids, natural pigments and odors, crude palm oil becomes refined-bleached-deodoried palm oil (RBD PO). The refined palm oil is close to colorless and transparent in liquid form.

In addition, according to the needs of different users, palm oil can be further fractionated and processed to get palm oleic acid (PFAD), palm oil (referred to as OLEAN), palm stearin (referred to as STEARINE or ST).

Automatic large scale palm oil refinery plant

Automatic large scale palm oil refinery plant

The business scope of Henan Doing Company:

1-20tpd small scale palm oil refinery plant

20-50tpd medium scale palm oil refinery plant

50-600tpd automatic large palm oil refinery plant

1-600tpd palm oil fractionation machine

Palm oil brief introduction:

Palm oil is extracted from palm pulp. In the fatty acid composition of palm oil, saturated acid accounts for 40% to 50%, and the rest is unsaturated acid neutralizing linoleic acid. Palm fruit is susceptible to decomposition of lipolytic enzymes before harvesting and palm oil production, and may also be affected during palm oil production process, palm oil storage and transportation.

Therefore, the content of free fatty acids in hair palm oil is high, generally about 10%, and high up to 30% sometimes. But the phospholipid content in palm oil is very low. So Henan Doing Company recommend automatic palm oil refinery plant with Dry Physical Palm Oil Refining Method.

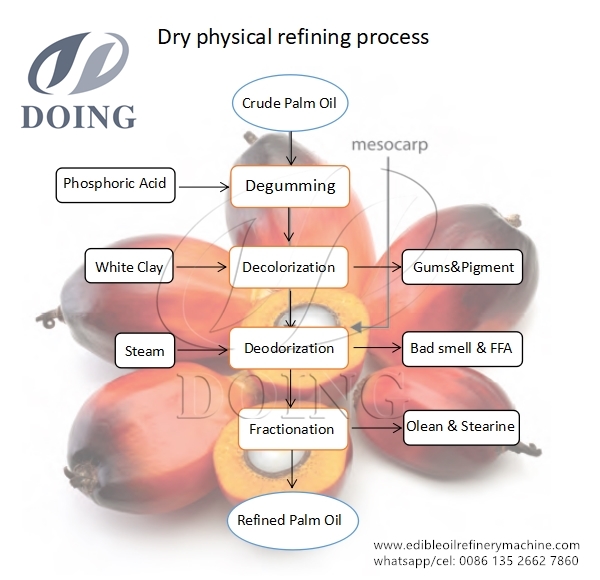

Palm oil refining process:

Dry physical refining process of automatic palm oil refinery plant

Dry physical refining process of automatic palm oil refinery plant

Dry physical refining process means that the degumming process don't use hot water, also called dry degumming process, which is suitable for oils with low phospholipid content (less than 200 mg/kg), such as palm oil, palm kernel oil, coconut oil and animal fats. The following is a brief introduction of Dry Physical Refining Process in automatic palm oil refinery plant.

1. Degumming Section:

Heat crude palm oil to 30-50℃, add moderate phosphoric acid, and then the non-hydrated phospholipids transforms hydrated phospholipids.

2. Decolorization Section:

Heat palm oil to 105-120℃, quantitatively add white clay and mix with palm oil. Utilization the adsorption of the white clay, the gums and the pigments are removed together. Besides, through leaf-filter's filtration process, thewaste white clay will be discharged.

3. Deodorization Section:

Deodorization tower and internal structure of palm oil refinery plant

Deodorization tower and internal structure of palm oil refinery plant

The main machine in palm oil refinery deodorization section is combined packing deodorization tower that have two parts. The slender part above is deacidification part and the thick part below is deodorization part. Input high temperature steam to remove free fatty acids and odor components from the oil. In addition, the deodorizing portion can also lower the peroxide value of the oil.

4. Fractionation section:

Palm oil fractionation machine

Palm oil fractionation machine

Palm oil fractionation plant devides into 3 parts, crystallazing, crystall growing/maturing, and filtration. After palm oil fractionation plant, palm oil is separated to several parts with different melting points, which can be used in different industrial usages.

The advantages of Dry Physical Palm Oil Refining:

◆ Low production consumption. Dry physical palm oil refining method needn't add alkli.

◆ Low cost of palm oil refining equipment. Dry physical palm oil refining method don't have neutralization process and washing process, so related machines are not required.

◆ No waste water and don't need wastewater treatment plant.

Doing Company has been specialized in palm oil refinery plant for decades. And our palm oil processing machine's technology and quotation are both our advantages to compete with other companies. If you are interested in setting up a palm oil refinery plant, our professional engineers can help you design and install according to your capacity and requirements.

Prev:Canola/ rapeseed oil refinery plant

Next:Nothing