How to regulate temperature while refining vegetable oil?

Tech / Chat on line / Give me a price / Date:2020-03-11

Generally, the temperature of different process while refining vegetable oil are different, and the requirement is very strict. They are decided by engineers when designing the vegetable oil refining process. So it doesn't need to regulate temperature frequently, and the things only to do for workers is to operate the machines according to the regulations.

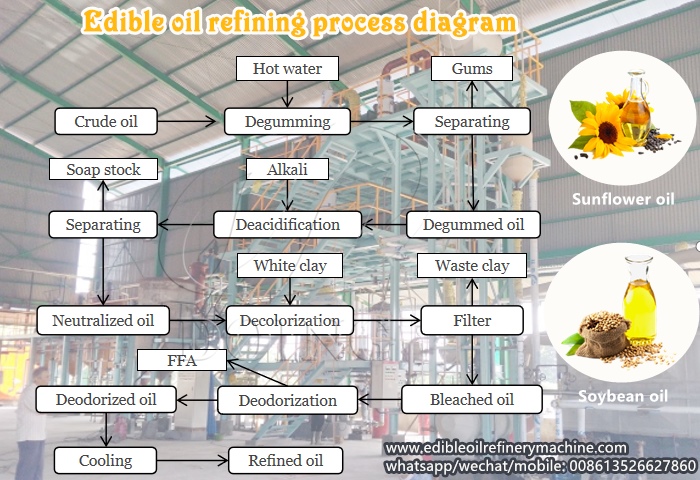

The complete vegetable oil refining process flow chart

The complete vegetable oil refining process flow chart

The complete vegetable oil refining process has four parts: degumming, deacidification, decolorization and deodorization. While refining vegetable oil, the crude oil is heated by heat conductive oil. So the first step is to increase the temperature of heat conductive oil to 85℃, and then it will be used in the whole process.

The temperature regulations of each step while refining vegetable oil:

| Step | Temperature regulations | Method | Purpose |

| Degumming | 65~75℃ | Hydration reaction | Remove gums |

| Deacidification | 85℃ | Neutralization reaction | Remove free fatty acid |

| Decolorization | 105℃ | Physical adsorption reaction | Remove pigment |

| Deodorization | 260℃ | Distillation reaction | Remove odors |

In deodorization step, if you want to use shorter time, you can use higher temperature. As experiment shows, in the range of deodorization temperature, increasing of every 17℃, deodorization period will reduce half. But more remarkable, if the temperature is over high, it will produce harmful substances, so you should make sure with engineers.

At last, I want to remind you again that while refining vegetable oil, the right operation of workers is very important. Only things they should do is to regulate the temperature according to the regulations. If you want to set up a vegetable oil refining plant, Doing Company engineers will be very glad to design the process and machine for you. And we can arrange engineers to provide installation guidance for you.