What advice can you give in order to produce well refined sunflower oil?

Tech / Chat on line / Give me a price / Date:2022-09-21

In order to produce well refined sunflower oil, we need to know what are the factors that affect the production of refined sunflower oil. The first is the quality of crude sunflower oil, and the second is the quality of sunflower oil refining machine.

Refined sunflower oil and sunflower oil refining machine

Refined sunflower oil and sunflower oil refining machine

1. If you want to produce well refined sunflower oil, Henan Glory recommends you to choose high-quality crude sunflower oil, then, how to get high-quality crude sunflower oil? On the one hand, you can choose a reliable crude sunflower oil manufacturer for direct purchase, on the other hand, you can produce high-quality crude sunflower oil yourself, Henan Glory can provide you with high-quality crude sunflower oil production equipment , there are three options for you to choose from:

Option 1: For small sunflower oil processing plants, you can choose a sunflower oil press or a small scale sunflower oil production line. The sunflower oil production equipment produced by Henan Glory has the advantages of low investment, multi-function, and low residual oil rate, which can help you obtain high-quality crude sunflower oil.

Small scale sunflower oil production line

Small scale sunflower oil production line

Option 2: For medium and large scale sunflower oil processing plants, Henan Glory engineers will design a complete sunflower oil production line for you, including cleaning, crushing, kernel shell separation, flaking, cooking, pressing, filtring, and finally get high-quality crude sunflower oil.

Complete sunflower oil production line

Complete sunflower oil production line

Option 3: For customers with sufficient budget, you can choose to be equipped with sunflower oil solvent extraction machine. The residual oil rate of sunflower oil solvent extraction machine is less than 1%, which can help you obtain more and better quality sunflower oil and achieve sunflower oil production maximizes profits.

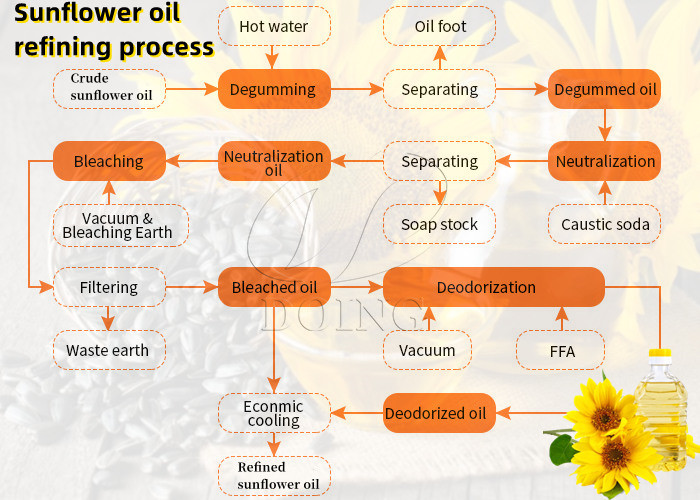

2. To produce well refined sunflower oil, high-quality sunflower oil refining machine is also essential. Let's first understand the process of sunflower oil refining:

The refining process generally includes four steps of degumming, deacidification, decolorization and deodorization. Degumming is the removal of phospholipids from crude sunflower oil. These impurities will not only destroy the stability of oil storage, but also affect the subsequent refining steps, so they must be removed first. Unrefined crude sunflower oil contains free fatty acids, which will make the oil prone to rancidity, so deacidification is required to remove free fatty acids. Add alkali (sodium hydroxide, NaOH) to produce soapstock through saponification reaction to remove acidic substances in oil. Soap stock also absorbs and removes other suspended impurities. Depigmentation by adding activated clay or activated carbon to absorb and remove pigments from the oil. First, it can make the oil products meet the preferences of consumers, and second, it can prolong the shelf life of the oil products. Deodorization uses low-pressure vacuum heating and hot steam to remove odor molecules in oil to achieve deodorization effect.

Sunflower oil refining process

Sunflower oil refining process

Therefore, if you want to produce well refined sunflower oil, Henan Glory recommends that you be equipped with complete sunflower oil refining machine, including alkali refining tanks, deodorization tanks, decolorization tanks, etc., which can maximize the removal of impurities in crude sunflower oil.

We have been focusing on cooking oil production equipment for more than ten years, and our products are exported to all over the world, especially Asia and Africa. Our cooking oil production equipment can not only produce high-quality cooking oil, but also be efficient, energy-saving and highly automated. Please feel free to contact us if necessary.