What is physical refining process?

Tech / Chat on line / Give me a price / Date:Nov 02, 2018

Economically designed Deodorizer and Physical Refining Plant for different Oil & Lower Capacities provides our company the edge. Physical Refining process is necessary for the removal of Free Fatty Acid, and also to use Steam Distillation method at high temperature and under high vacuum; it’s then followed by Deodorization and before deodorization for removal of free fatty acid an extra Technical facility is also added.

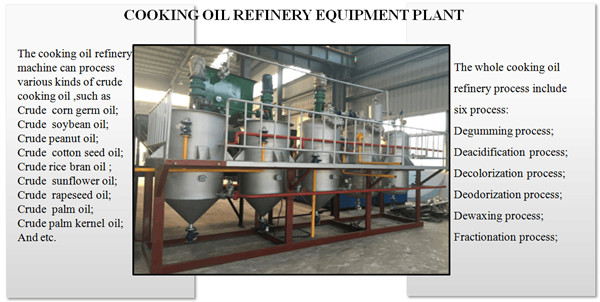

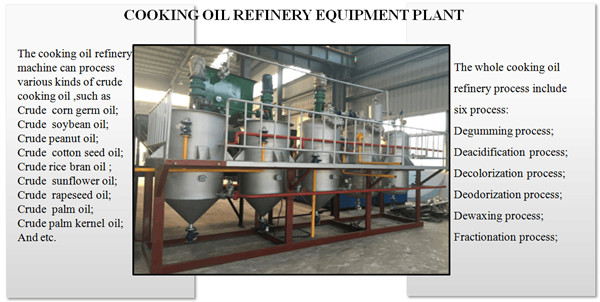

Edible oil refining plant applications and process

Unacceptable odor due to Steam Deodorization process is removed through Steam Distillation; plus the Odoriferous Compounds are stripped off with the help of live injected steam into heated oil under high vacuum.

The features of the Physical Refining & Deodorization are as follows:

Large surface area exposure to vacuum.

Minimum carry over of oil with fatty acids.

Maximum heat recovery.

Low steam consumption.

No packing / filling material inside.

No short circuit of oil in process.

Practically - No Maintenance.

No Trans-isomer generation.

Quick & Maximum flexibility in feed material.

Suitable temperature for addition of antioxidant

Edible oil refining plant applications and process

The features of the Physical Refining & Deodorization are as follows:

Large surface area exposure to vacuum.

Minimum carry over of oil with fatty acids.

Maximum heat recovery.

Low steam consumption.

No packing / filling material inside.

No short circuit of oil in process.

Practically - No Maintenance.

No Trans-isomer generation.

Quick & Maximum flexibility in feed material.

Suitable temperature for addition of antioxidant

Call us

Call us Chat online

Chat online