How to refine peanut oil processed in small workshops?

Tech / Chat on line / Give me a price / Date:2022-09-30

With the awakening of people's awareness of food safety, the era of "natural and pollution-free" ground-pressed peanut oil in private oil mills has passed, and it is time for oil mills to keep pace with the times. According to your processing capacity and investment budget, Glory can configure a set of cooking oil refining machine for your oil mill to refine the peanut oil processed by the oil mill, obtain peanut oil that meets the national standard, and expand product sales!

Peanut oil photo

Peanut oil photo

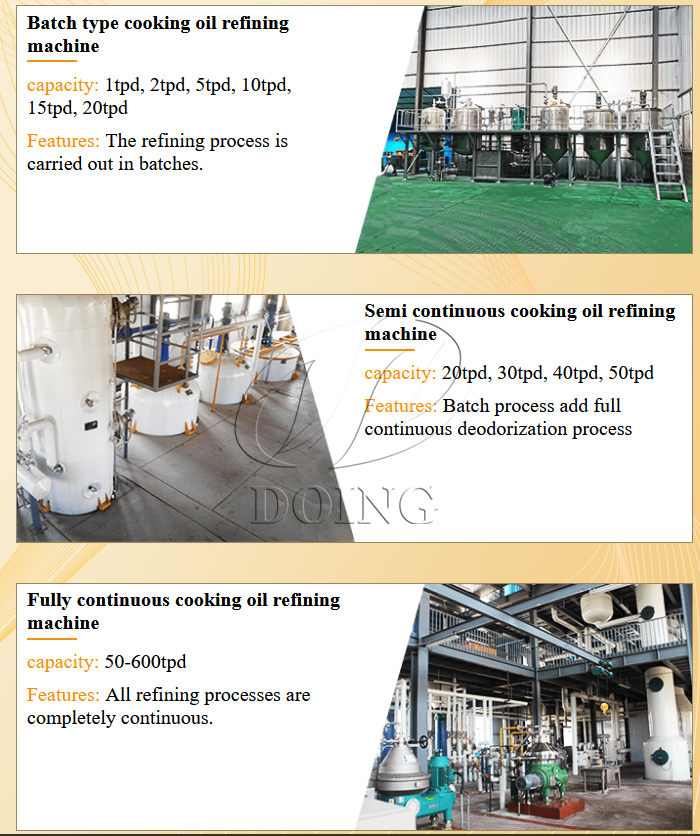

The ground-pressed peanut oil is dark in color and turbid, giving people a feeling of uncleanness. To solve this problem, it is necessary to purify and remove impurities through cooking oil refining machine. Which cooking oil refining machine is suitable for small workshops? It mainly depends on your daily processing capacity. Glory Company can design and produce three kinds of cooking oil refining machine: batch type, semi-continuous type and full continuous type.

3 kinds of peanut oil refining machine

3 kinds of peanut oil refining machine

Batch type cooking oil refining machine is suitable for small oil mills or oil plants with a daily processing capacity of less than 20 tons. It has small investment, small equipment footprint, simple and flexible operation, and is also suitable for frequent replacement of various oils. Although batch type cooking oil refining machine is cheap, its process is the same as semi-continuous and fully continuous refining machine, including four sections of degumming, deacidification, decolorization and deodorization. After four refining sections, you can get national standard grade 1 oil.

How much throughput is suitable for semi-continuous and full-continuous refining machine? What are the advantages? The semi-continuous refining machine can be designed with a daily processing capacity of 5-30 tons. The main advantage is in the last step. The deodorization pot is replaced by a deodorization tower, and the deodorization section can be carried out automatically and continuously, with high efficiency and good effect. If the budget is sufficient, semi-continuous refining machine can also be considered.

The daily processing capacity of the fully continuous refining machine is generally more than 30 tons, and it is used by large cooking oil processing plants. Advantages: A lot of auxiliary equipment has been added, so that the four sections of degumming, deacidification, decolorization and deodorization can be carried out automatically and continuously. The investment in full continuous refining machine will be relatively large, and it is not recommended that the owner of the oil mill consider this plan.

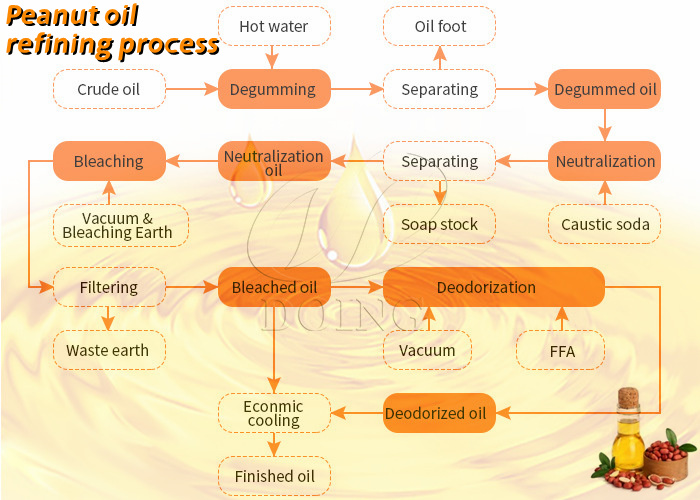

As for how the batch type cooking oil refining machine refines peanut oil? Glory will briefly introduce to you.

Peanut oil refining process

Peanut oil refining process

1. Degumming: Peanut crude oil is degummed by adding hot water/phosphoric acid in the refining pot;

2. Deacidification: enter the alkali smelting pot, react with the lye, and remove free fatty acids;

3. Decolorization: white clay is added to the decolorization pot to absorb the pigment and make the peanut oil lighter;

4. Deodorization: Under vacuum conditions, direct steam volatilizes odorous substances to achieve the purpose of deodorization.

After these four refining processes, you can obtain peanut oil with clear color, no peculiar smell and high nutritional value, which can be directly sold in large supermarkets.

If you, as an oil mill owner, want to upgrade your oil mill equipment, improve product quality, and expand product sales, you are welcome to contact us at any time, and our technical team will give you a satisfactory equipment solution! Choose Glory to escort your oil mill production!