HomeTechWhat should be paid attention to in making the design and layout of cooking oil refinery plant?

HomeTechWhat should be paid attention to in making the design and layout of cooking oil refinery plant?

What should be paid attention to in making the design and layout of cooking oil refinery plant?

Tech / Chat on line / Give me a price / Date:2022-12-09

The design and layout of cooking oil refinery plant is very crucial for the smoothness of the cooking oil refining process, increase the oil production capacity and lower the operational cost. The requirements for making the design and layout of cooking oil refinery plant includes the following main parts.

Cooking oil refinery plant layout design

The reqirements of design and layout of cooking oil refinery plant

The reqirements of design and layout of cooking oil refinery plant

1. Meet the requirements of cooking oil refining process

The design of the cooking oil refinery plant should fully consider the characteristics of cooking oil refining, including the refining process of cooking oil, raw materials, finished product transportation means and methods, etc. In this way, the design of the factory building is more in line with the production conditions, and the subsequent production efficiency can be improved.

2. Reasonable selection of factory structure

Selecting a suitable structural system according to the requirements of production technology, materials and construction conditions is also very important for saving investment costs and shortening the construction period. A suitable factory structure is also conducive to guaranteeing production conditions.

3. Ensure a good operating environment

A standard cooking oil refinery plant should have good lighting, ventilation and landscaping. And it also has good control over noise, temperature, humidity and other conditions.

4. Scientific organization space

The scientific organizational space and room layout meet the needs of production while maintaining good hygienic conditions.

Professional engineers can design suitable solutions for you according to factors such as plant area. Henan Glory Company is more than 10 years oil machine manufacturer in the field and we have experienced engineers who will help you design cooking oil refinery plant and installation and so on. Let me give two layouts of cooking oil refinery plant for reference.

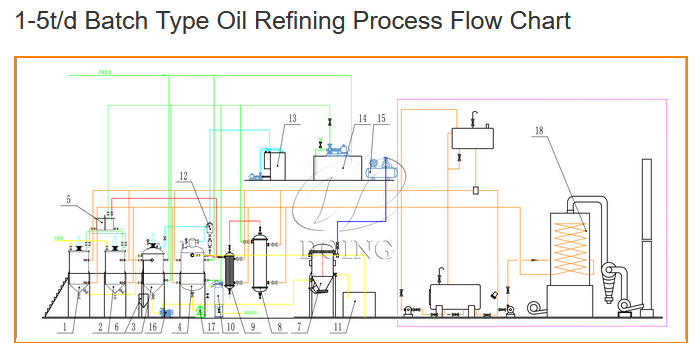

Small scale cooking oil refinery plant layout

Small scale cooking oil refinery plant flow chart

Small scale cooking oil refinery plant flow chart

This small scale cooking oil refinery plant could need some main refining machines, including two refining tanks, decolorization tank, deodorization tank, white clay tank and some auxiliary equipment.(Recommend reading: Batch type edible oil refinery plant)

Complete cooking oil refining process

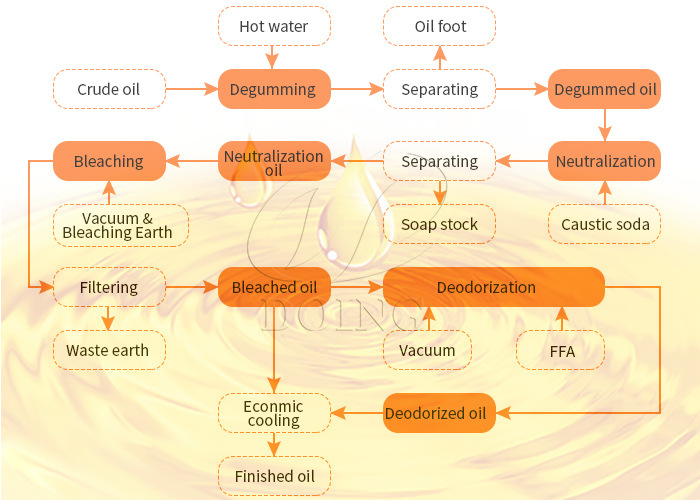

Cooking oil refinery plant layout includes a series of processes as are described below.

Complete cooking oil refining process

Complete cooking oil refining process

1. Degumming

Generally, crude cooking oil has less gum, and can be degummed by dry method, that is, adding phosphoric acid solution to crude cooking oil in order to make peptized impurities into agglomerates, and the peptized impurities can be removed after sedimentation.

2. Deacidification

Cooking oil batch refining equipment generally uses chemical deacidification to remove free fatty acids, which is to add lye to crude cooking oil to neutralize it with free fatty acids. The soap would be formed after neutralizing, which be removed after edimentation, thereby the free fatty acids is removed.

3. Decolorization

The specific operation process of decolorization is to add clay to crude cooking oil to absorb pigments and other impurities in the oil, and then use the leaf filter to filter out the waste clay in the oil.

4. Deodorization

Deodorization is to inject direct steam into crude cooking oil, and take advantage of the difference in volatility between oil and odorous substances to take away odors. After deodorization, the quality of cooking oil is improved, and the smoke point and stability are also improved.

Henan Glory Company provides optimal the design and layout of cooking oil refinery plant, from small scale to large scale. If you are interested to know more about factory layout for cooking oil industry, please feel free to contact us any time.