HomeTechHow to achieve refined purification in the cooking oil extraction process? What machines are available?

HomeTechHow to achieve refined purification in the cooking oil extraction process? What machines are available?

How to achieve refined purification in the cooking oil extraction process? What machines are available?

Tech / Chat on line / Give me a price / Date:2022-08-26

Cooking oil is extracted by pretreatment and pressing, but the crude cooking oil obtained in this process may contain a small amount of impurities, which affects the quality and stability of oil products. We usually use cooking oil refining equipment to refine and purify crude cooking oil to obtain higher quality cooking oil. How is cooking oil refined and purified? Let's take a look.

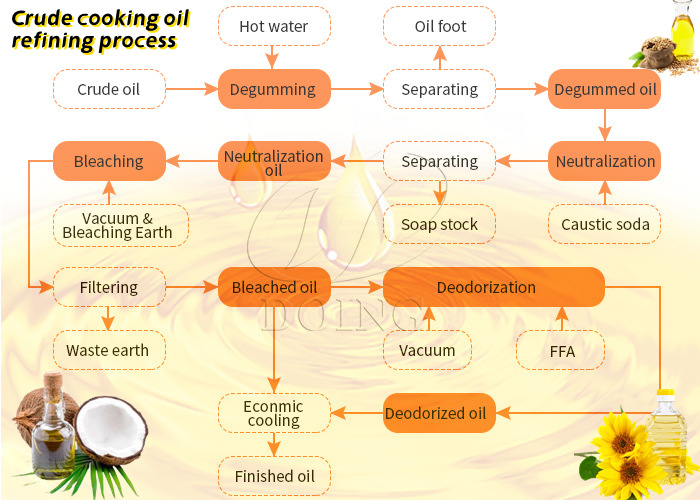

Cooking oil refining process

Cooking oil refining process

First, we will degumming the cooking oil. The specific method is: adding water or food-grade phosphoric acid with a concentration of 85% or 75% to form micelles, and opening the valve to release the micelles. It should be noted that batch and semi-continuous refining lines do not have a separate degumming section, while full continuous refining lines, degumming and deacidification are done in different equipment.

Then, the cooking oil is deacidified, and the specific method is: adding NaOH for acid-base neutralization to remove free fatty acids in the oil.

Then the deacidified oil enters the decolorization section. The specific method is as follows: adding a decolorizing agent to absorb impurities, and then separating the oil in the decolorizing agent with a filtering device to achieve the purpose of decolorization.

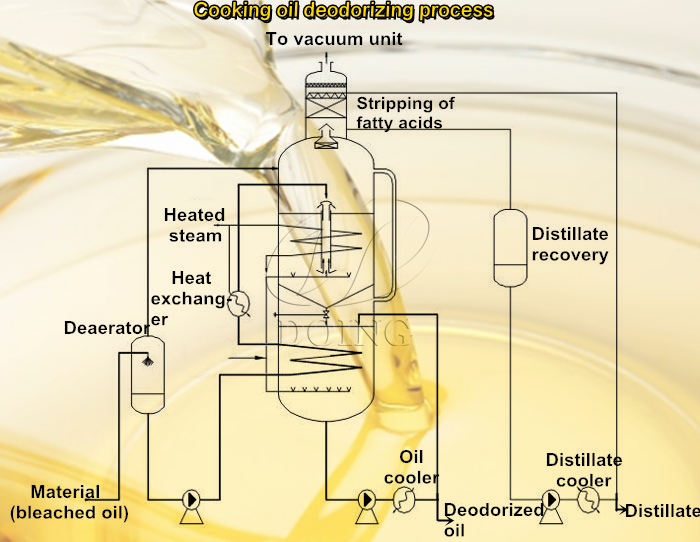

The last step is to deodorize the decolorized oil. The specific method is: under the vacuum condition of 220-260 °C, according to the different volatilization points of the oil and the odorous substance, steam is introduced for stripping to remove the odor.

Cooking oil decolorizing process

Cooking oil decolorizing process

Cooking oil refining mainly includes batch type cooking oil refining, semi-continuous type cooking oil refining and fully continuous type cooking oil refining. You can choose according to processing capacity. Below I will introduce to you what equipment is included in different types of cooking oil refining methods.

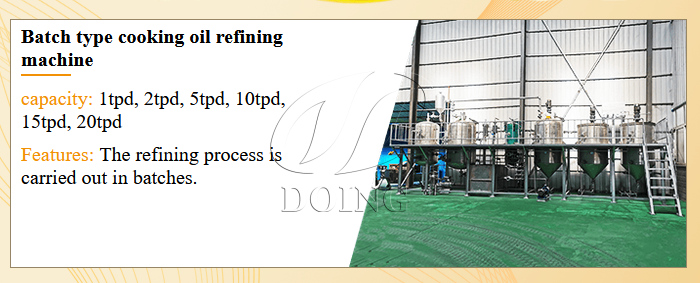

Batch type cooking oil refining equipment includes: refining pot (or alkali refining pot), decolorizing pot, deodorizing pot, filter, vacuum pump, heat conduction oil furnace, etc.

Batch type cooking oil refining equipment

Batch type cooking oil refining equipment

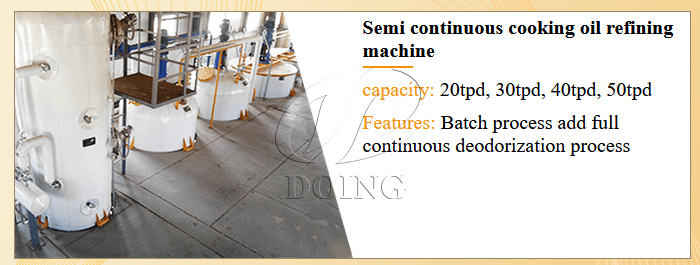

Semi-continuous type cooking oil refining equipment includes: refining pot (or alkali refining pot), decolorizing pot, filter, gas separator, spiral plate heat exchanger, cooler, deodorizing tower, fatty acid trap, shield pump, fatty acid circulation tank, heat conduction Oil furnace system, steam boiler system, vacuum system, etc.

Semi-continuous type cooking oil refining equipment

Semi-continuous type cooking oil refining equipment

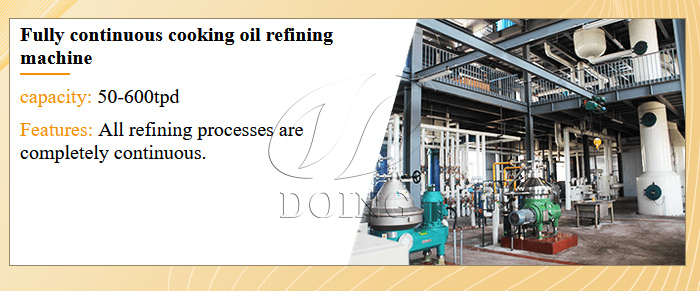

Fully continuous type cooking oil refining equipment includes: crude oil filter, plate heat exchanger, centrifugal mixer (or multi-effect mixer), acid reaction tank, alkali reaction tank, disc centrifuge, dryer, high-level clay tank, oil and soil preheating Mixer tank, decolorization tower, leaf filter, spiral plate heat exchanger, heat transfer oil heater, deodorization tower, fatty acid trap, fatty acid circulation tank, cooler, shield pump, cooling water tower, oil pump, four-stage steam injection Pumps, water jet pumps, heat transfer oil furnace systems (or high pressure steam boilers), steam boiler systems, fuel tanks, etc.

Fully continuous type cooking oil refining equipment

Fully continuous type cooking oil refining equipment

Of course, the configuration of these equipment is not unchangeable, you can choose the equipment you need according to your budget, or you can consult Henan Glory Company, we have professional engineers to customize one-to-one cooking oil refining solutions for you, providing high-quality cooking oil refining equipment, Henan Glory welcomes your consultation.