A comprehensive guide to the cooking oil chemical refining process

Tech / Chat on line / Give me a price / Date:2024-10-12

Cooking oil refining is a critical step in transforming crude oil into a high-quality, market-ready product. At Henan Glory Oils & Fats Engineering Co., Ltd, we offer comprehensive solutions for cooking oil chemical refining, ensuring your cooking oil meets industry standards for purity, taste, and shelf life. This comprehensive guide will take you through the key processes involved in the cooking oil chemical refining: degumming, deacidification, decolorization and deodorization, each step plays a crucial role in refining process.

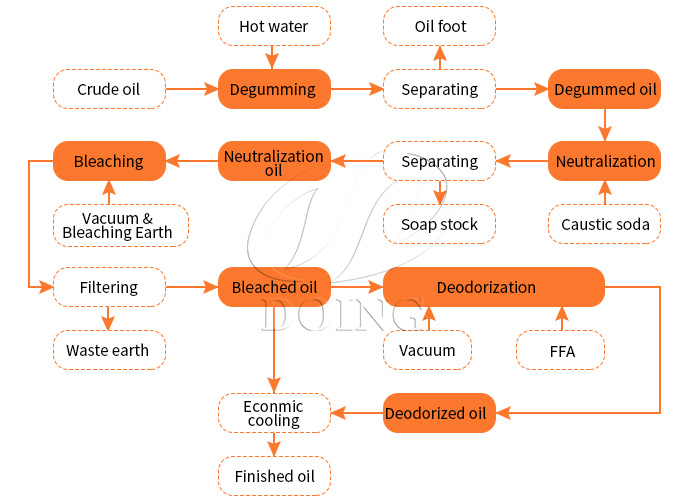

Cooking oil chemical refining flow

Cooking oil chemical refining flow

Degumming

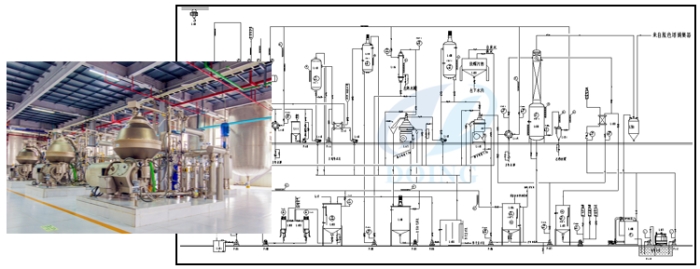

This initial step of cooking oil chemical refining involves removing gums and other phospholipids from the crude oil. These impurities can affect the oil’s stability and quality. Our degumming systems utilize water to effectively separate the gums, leaving behind cleaner oil ready for the next stage.

Deacidification

Also known as neutralization, deacidification is the process of removing free fatty acids (FFAs) that contribute to off-flavors and a shorter shelf life. During this step, we use alkali solutions to neutralize the FFAs, converting them into soap stock that can be easily separated. The acidity of the separated oil will be greatly reduced. This step ensures a smoother and more stable final product.

Cooking oil degumming and deacidification plant

Cooking oil degumming and deacidification plant

Decolorization

The stage involves removing unwanted color pigments and other compounds that affect the color of the oil. Using specially designed filters and absorbent materials, this step guarantee a brighter, more appealing oil without affecting its nutritional value.

Deodorization

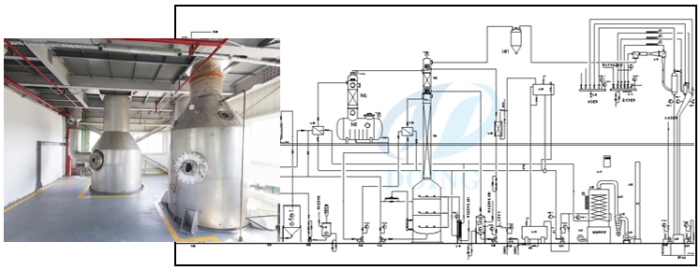

The final step in the chemical refining process is deodorization, which eliminates remaining volatile compounds responsible for undesirable odors and flavors and suitable for various cooking purposes. This process needs to be carried out under vacuum and at very high temperatures in order to remove odors in the best possible way.

Cooking oil deodorization plant

Cooking oil deodorization plant

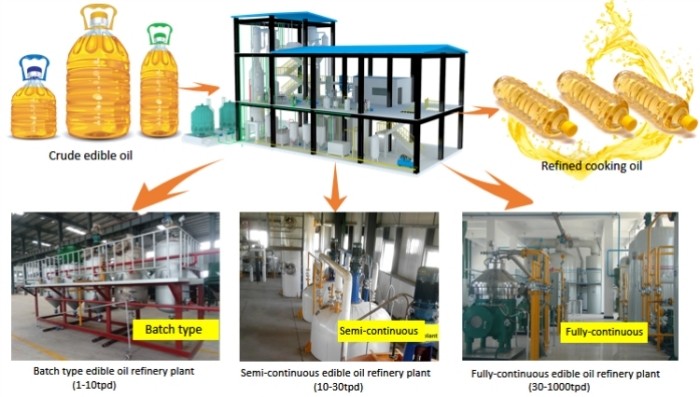

According to the type of refining, Henan Glory divides it into Batch type edible oil refinery plant (0.5-20tpd), Semi-continuous edible oil refinery plant (10-50tpd) and Full-continuous edible oil refinery plant (≥30tpd).

The cooking oil chemical refining requires a lot of equipment, including refining tank, centrifugal, vacuum pump, thermal oil furnace, vacuum filter, deodorization tower, crystallizing tank, etc. It should be noted that different types of refining require different equipment.

Three types of cooking oil refinery plant

Three types of cooking oil refinery plant

Henan Glory chemical refining plant is tailored to meet the needs of small, medium, and large-scale producers. Whether you’re refining cooking oil for retail or industrial use, our technology ensures a high-quality end product that meets all regulatory standards. Contact us for more information on how our advanced chemical refining solutions can elevate your cooking oil production!