Dry degumming process of palm oil

Industry News / Chat on line / Give me a price / Date:Mar 27, 2018

Automatic palm oil refinery plant

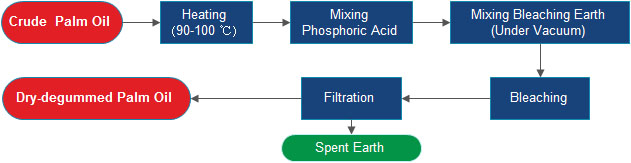

Dry degumming process of palm oil:

Dry degumming is widely applied in refining low phosphatide oil such as palm oil, or used for preparing oils for further physical refining. Gums are removed through precipitation by acid conditioning and via filtration in the bleaching process, rather than centrifugal separation. It is a well-proven degumming method featured of cost effective. Below shows the flow diagram of dry degumming process of palm oil refining.

Palm oil degumming process

Except dry degumming, there are also other types of degumming methods applied in vegetable oil refining plant, such as water degumming and acid degumming. The main differences between these types lie in processing method and chemicals used. Besides, the selection degumming method is based on the content of phosphatides in the crude oil.

Water Degumming: Water degumming is suggested for refining crude oil with phosphorus content around 200ppm, such as soybean oil. The crude oil is firstly go through precipitatation by pure water hydration. Then gums are removed from the crude oil by using the principle of centrifugal separation. Water is the key agent in this degumming process. Below shows the flow diagram of water-degumming process of oil refining plant.

Acid degumming: Through acid conditioning process, gums are precipitated from the crude oil and then be removed by centrifugal separation. It is normally used in refining process of rice bran and sunflower oil.

Feel free to contact us if you are interested in detailed information about our refining solution of crude palm oil. We are always at your services!

The following is some onsite photos of our edible oil refining projects including refining of palm oil.

Palm oil refining machine installation site in Kenya

Call us

Call us Chat online

Chat online