Degumming process of edible oil refinery plant

Industry News / Chat on line / Give me a price / Date:Jun 09, 2017

Small scale edible oil refining plant

Technically, degumming of edible oil is referred as an operation of purification in palm oil refining process, since crude edible oil normally contains impurities in the colloidal state or dissolved in them. In degumming process, phospholipids featured of strong emulsifying action are removed by a variety of treatments. The objective is achieved by treating the crude edible oil with specified quantity of food grade acid, normally phosphoric or citric acid of certain concentration, either singly or in combination. The precipitated materials are then removed by centrifuging, filtering or adsorption. In short, degumming of edible oil is a process of removing unwanted gums, so that to ensure the stability of the edible oil in later stage of refining plant.

Edible oil degumming process

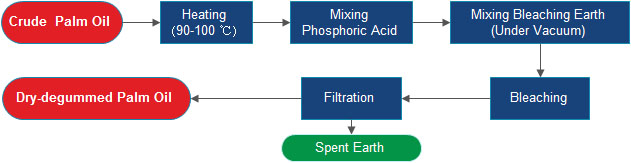

Dry degumming is widely applied in refining low phosphatide oil such as edible oil, or used for preparing oils for further physical refining. Gums are removed through precipitation by acid conditioning and via filtration in the bleaching process, rather than centrifugal separation. It is a well-proven degumming method featured of cost effective.

Dry degumming process of edible oil: For crude edible oil refining plant, drying degumming process is suggested. Classically, crude edible oil is first mixed with about 0.05– 0.1% concentrated phosphoric acid. Then, after a short retention time, about 1 or 2% acid-activated bleaching earth is added under vacuum at a temperature of 80–120℃. After a suitable contact time, the spent degumming is removed by filtration. Phosphoric acid is mainly used by edible oil refiners especially in world, due to economical reasons. However, citric acid is also used in some cases. The critical factor affecting the quality of refined edible oil is the introduced amount of acid. Either over or under dosage can lead to darkening and offflavor problems of the edible oil.

Except dry degumming, there are also other types of degumming methods applied in vegetable oil refining plant, such as water degumming and acid degumming. The main differences between these types lie in processing method and chemicals used. Besides, the selection degumming method is based on the content of phosphatides in the crude oil.

Water Degumming: Water degumming is suggested for refining crude oil with phosphorus content around 200ppm, such as soybean oil. The crude oil is firstly go through precipitatation by pure water hydration. Then gums are removed from the crude oil by using the principle of centrifugal separation. Water is the key agent in this degumming process.

Acid degumming: Through acid conditioning process, gums are precipitated from the crude oil and then be removed by centrifugal separation. It is normally used in refining process of rice bran and sunflower oil.

Call us

Call us Chat online

Chat online