Automatic type vegetable oil refinery plant

Fully Continuous Edible Oil Refinery / Chat on line / Give me a price / Date:Apr 18, 2017

Different types vegetable oil reifnery plant

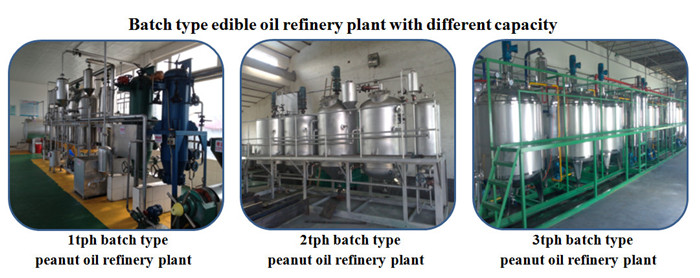

Henan Doing Company is a leading designer, manufacturer and exporter of state of the art vegetable oil refinery plants in both continuous type vegetable oil refinery plant and batch type vegetable oil refinery plant. It is very essential that the crude oil obtained from oil press workshop and solvent extraction workshop get refined in the vegetable oil refinery plants before it is utilized directly. Our continuous vegetable oil refinery plant gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil.

Our high-tech vegetable oil refinery plant finds an extensive application for all types of crude oil like cotton seed, soyabean, sunflower, palm oil, rice bran oil etc.

Process Description for Continuous Vegetable Oil Refinery Plant:

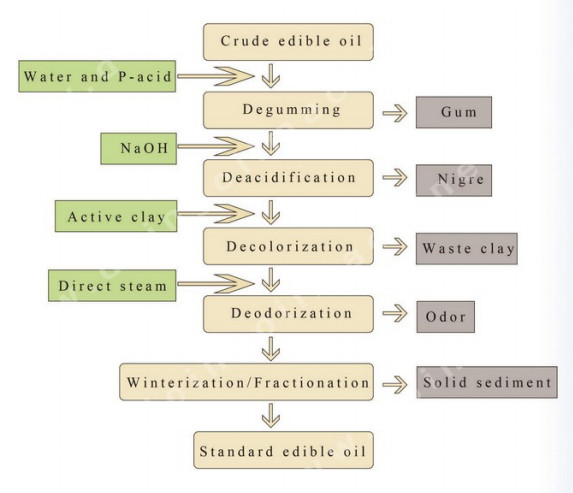

Continuous refinery line comprises of the following different processes:

Degumming or Pretreatment Section

Neutralizing Section

Bleaching Section

Deodorizing Section

Dewaxing section

Vegetable oil refinery process

Our continuous type vegetable oil refinery plant can adopt two methods of refining,ther are physical refining and chemical refining.Different vegetable oil refining methods have different features.

Our physical method of refining removes the Free Fatty Acids in single stage of deodorization process while the gum content from the crude oil is removed in the degumming process. In physical refining, comparatively more FFA is distilled out giving a high oil refining rate with minimum oil loss. For oils like palm oil there is no necessity to go for alkali refining. After pretreatment of oil the oil is deodorized cum physically refined. Henan Doing Company provides a perfect physical refining process to their clients with best deals and competitive industry prices.

Vegetable Oil Refinery Plant- Chemical Refining:

Chemical refining is most widely used method for refining all types of crude oils. Chemical method of refining removes the Free Fatty Acids and other impurities in a chemical way by Acid-Base neutralization process. Caustic soda is used as a base for this method. The addition of Caustic Soda to the acid completes the neutralization. This results in the formation of sodium soaps and gums which are then separated by Separators & Centrifuges. The neutralized oil is subsequently bleached and deodorized. We offer highly productive chemical refining technology with effective refining techniques. Our oil refinery plants are working successfully all around the world.

Available capacity for continuous type vegetable oil refinery system: 50TPD to 1200TPD.

Call us

Call us Chat online

Chat online